Why need us?

RFID is bringing a huge revolution to the field of warehousing and logistics. It can help flow, and the warehousing management to achieve full automation, shorten the time of

operation, greatly reduce artificial operating costs, and at the same time apply automated means to improve the

efficiency of warehousing and logistics and precision, increase logistics throughput, improve warehousing and logistics

management efficiency。

RFID Application Advantage

The application automatically completes the inbound and outbound status changes when items enter or leave the warehouse, eliminating the need for manual intervention. As a result, real-time updates are achieved, significantly improving efficiency and ensuring the company can accurately and promptly grasp the true inventory levels.

Furthermore, long-distance reading and writing capabilities make inventory management and item retrieval faster and more efficient. Additionally, the mobility of RFID technology provides precision that surpasses human capabilities. With full automation, the system delivers more precise and optimized management, enabling features such as automatic stock alerts, batch management, shelf-life tracking, and priority storage for items with longer storage periods.

Moreover, fully automated and intelligent warehouse management ensures real-time data updates, making multi-warehouse collaboration more efficient and accurate. By integrating RFID technology, the supply chain can be managed comprehensively, covering warehousing logistics, channel sales, and product anti-counterfeiting. This integration allows for seamless control over orders, order execution, supply cycles, quality control, manufacturing, logistics, warehousing, distribution, sales, and anti-counterfeiting operations.

As a result, businesses benefit from real-time, efficient, and highly accurate operations, leading to faster response times, lower turnover rates, and reduced inventory levels. Ultimately, this drives an overall improvement in business management and operational efficiency.

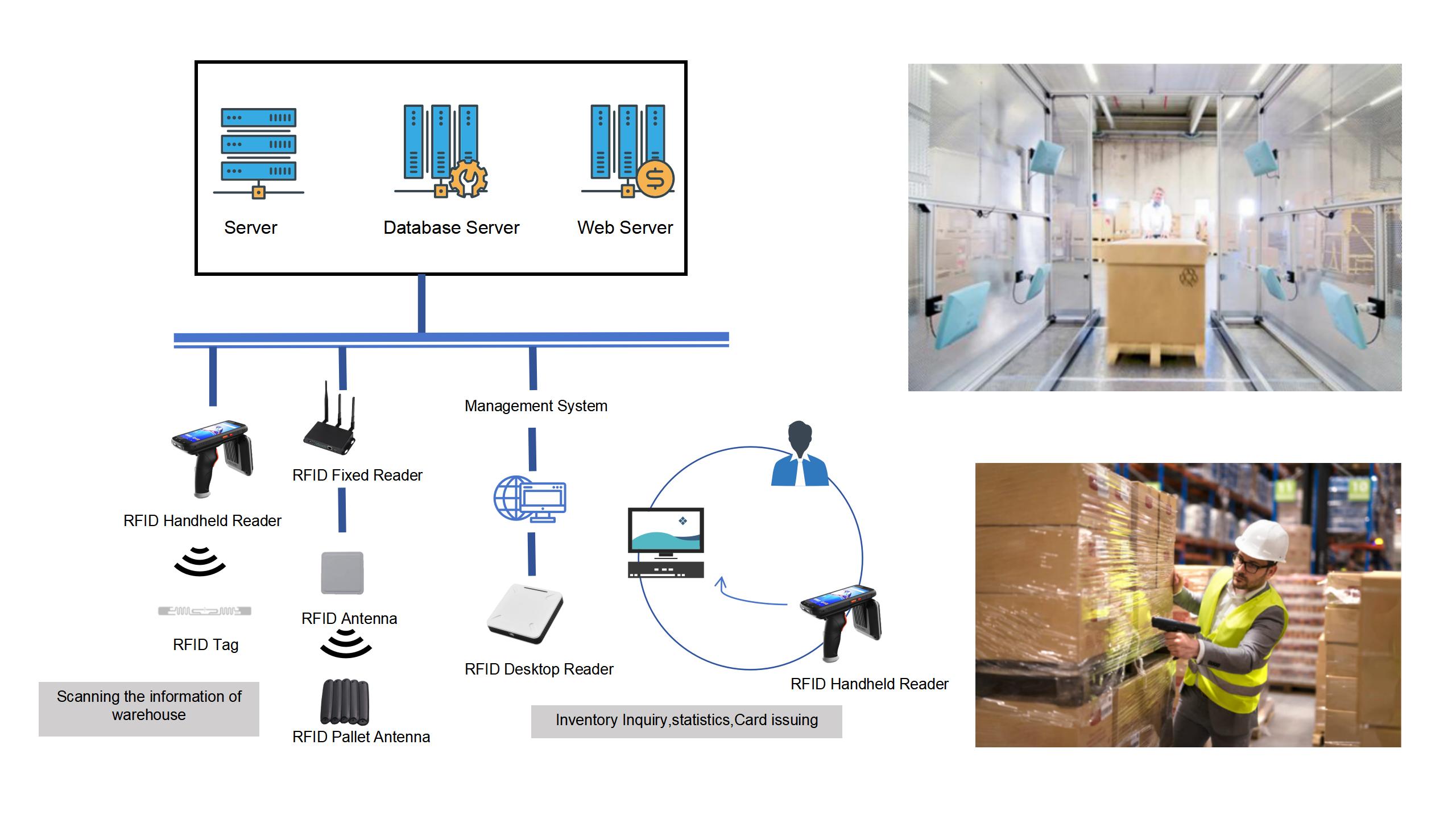

Warehouse Inventory system (system architecture diagram)

RFID Tag Implementation

- Attach RFID tags to packages/pallets.

- Label product name, specifications, storage location, and delivery details.

System Setup

- Install RFID readers at warehouse exits and distribution channels.

- Enable automatic identification of goods during inbound/outbound processes.

Supply Chain Automation

- Track goods across procurement, storage, manufacturing, packaging, transportation, distribution, sales, and service.

- Use RFID as the core data carrier for real-time visibility.

Automated Inventory Management

- UHF RFID devices at warehouse gates enable long-range, multi-tag scanning.

- Monitor stock levels, transfers, and shipments automatically.

- Ensure accurate data collection for warehouse operations (in/outbound, counting).

Intelligent Warehouse Features

- Apply FIFO (First-In-First-Out) logic based on batch/shelf-life data.

- Detect overstock, shortages, or slow-selling items automatically.

Multi-Warehouse Coordination

- Manage distributed warehouses (types/regions) with real-time inventory tracking.

- Automate/semi-automate replenishment, sorting, and distribution.

Related Products:

Reader:UHF RFID Fixed Reader QW-301

Antenna:UHF RFID Antenna QW-A260

Tag: UHF RFID Anti-metal Tag QW-K10324